2109 Ergonomics and Lifting in the Kitchen

Definition and Importance of Ergonomics

Ergonomics is the study of designing workspaces and work practices to fit the capabilities and limitations of the human body. In foodservice, ergonomics is essential to ensure the safety, comfort, and efficiency of employees, thereby reducing the risk of injury and enhancing productivity.

Overview of Common Ergonomic Issues in Foodservice Environments

Foodservice environments often involve repetitive motions, prolonged standing, heavy lifting, and awkward postures, which can lead to musculoskeletal injuries. Common ergonomic issues include:

- Back strain from lifting heavy objects.

- Repetitive strain injuries from tasks like chopping and stirring.

- Fatigue from prolonged standing.

- Wrist and hand injuries from using poorly designed tools.

Principles of Ergonomic Design

Understanding Human Anatomy and Movement

A basic understanding of human anatomy and how the body moves is crucial for designing ergonomic workstations. Key areas of focus include:

- Spine Alignment and the Importance of Maintaining a Neutral Posture: Spine alignment refers to maintaining the natural curves of the spine. A neutral posture minimizes stress on the body and helps prevent musculoskeletal injuries.

- The Mechanics of Lifting and Carrying Objects: Proper techniques for lifting and carrying heavy objects are essential to prevent back and spine injuries.

- The Impact of Repetitive Movements on Joints and Muscles: Repetitive movements can cause excessive strain on muscles and joints, leading to repetitive strain injuries.

Key Ergonomic Principles: Posture, Repetition, Force, and Recovery

- Posture: Maintaining a neutral and balanced posture is essential to minimize stress on the body. Proper posture supports spine alignment and enhances the functionality of the musculoskeletal system.

- Repetition: Repetitive tasks can lead to overuse injuries. Reducing repetitive tasks or incorporating breaks allows muscles and joints to recover, preventing excessive strain.

- Force: Minimizing the amount of force required to perform tasks reduces strain on muscles and joints. Using lightweight tools and applying proper lifting techniques can help achieve this.

- Recovery: Allowing sufficient recovery time helps prevent fatigue and injuries. Regular breaks and task rotations aid in muscle and joint recovery, enhancing overall work performance.

Designing Ergonomic Workstations

Layout and Organization of Kitchen Workstations

Efficient Workflow: Arrange workstations to minimize unnecessary movement and ensure a smooth workflow. This involves placing equipment, tools, and ingredients in a logical sequence to streamline tasks and reduce the distance employees need to move.

Accessibility: Ensure tools and ingredients are within easy reach to reduce reaching and bending. Frequently used items should be stored at waist height, within arm’s reach, to minimize physical strain.

Proper Heights for Countertops, Cutting Boards, and Equipment

Countertop Heights: Typically, countertops should be 36-40 inches high. However, adjustable countertops are ideal to accommodate different users, allowing for a more personalized and comfortable working height.

Cutting Board Heights: Cutting boards should be about 4 inches below elbow height to allow for comfortable cutting and chopping, reducing shoulder strain and promoting a neutral wrist position.

Equipment Placement: Heavy and frequently used equipment should be stored between knee and shoulder height to avoid excessive bending or reaching. This placement helps prevent back and shoulder injuries.

Reducing the Need for Bending, Reaching, and Twisting

Shelving and Storage: Use pull-out shelves and drawers to minimize bending and reaching. These storage solutions make it easier to access items without having to lean over or squat down.

Rotating Platforms: Implement lazy susans or rotating platforms in cabinets and on countertops to reduce twisting motions. These platforms make it easier to access items stored at the back of shelves or counters.

Use of Adjustable Equipment and Furniture

Adjustable Tables and Stools: Use adjustable-height tables and stools to accommodate different tasks and user heights. This flexibility allows employees to work at a height that is comfortable and reduces strain on their bodies.

Ergonomic Tools: Provide tools with adjustable handles or designs that promote a neutral wrist position. Ergonomic tools can help reduce strain on the hands and wrists, preventing repetitive strain injuries.

Implementing Ergonomic Solutions

Anti-Fatigue Mats: Benefits and Placement

Benefits: Anti-fatigue mats reduce fatigue and discomfort from prolonged standing and improve circulation. These mats help alleviate foot, leg, and back pain for workers who stand on hard surfaces for extended periods.

Placement: Place mats in areas where staff stand for extended periods, such as prep stations, cashier areas, and food service counters. Regular cleaning and maintenance of the mats are essential to ensure hygiene and longevity.

Proper Footwear to Reduce Strain and Enhance Comfort

Supportive Shoes: Shoes with good arch support and cushioning reduce foot strain and improve overall posture. These shoes enhance comfort for staff who stand or walk for long periods, preventing foot pain.

Non-Slip Soles: Use shoes with non-slip soles to ensure safety by preventing slips and falls. This is particularly important in kitchens and service areas where floors may be wet or greasy.

Tools and Equipment That Support Ergonomic Practices

Lightweight Utensils: Use lightweight utensils to reduce the effort required and decrease the strain on the musculoskeletal system. Lightweight knives, pots, and other kitchen tools require less force to handle.

Ergonomically Designed Handles: Provide tools with handles that promote a neutral wrist position and reduce grip force. Ergonomic handles reduce strain on the hands and wrists, preventing repetitive strain injuries. Examples include knives with soft grips and pots with comfortable handles.

Preventing Musculoskeletal Injuries

Common Musculoskeletal Injuries in Foodservice and Their Causes

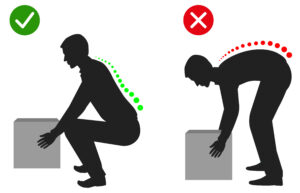

Back Strain: Often caused by improper lifting techniques, back strain is a common injury in foodservice environments where heavy lifting is frequent. Incorrect bending and lifting can put excessive stress on the back muscles and spine.

Carpal Tunnel Syndrome: Resulting from repetitive motions and poor wrist posture, carpal tunnel syndrome affects the hands and wrists. This condition is common among foodservice workers who perform repetitive tasks such as chopping, stirring, and lifting.

Tendinitis: From repetitive motions and overuse, tendinitis is an inflammation of the tendons. This injury is frequently seen in workers who engage in repetitive tasks without adequate rest or proper technique.

Techniques for Lifting, Carrying, and Moving Heavy Objects Safely

Lifting Techniques:

- Bend at the Knees, Not the Waist: Use your legs to lift, not your back, to avoid straining your spine.

- Keep the Load Close to the Body: Holding the load close to your body helps maintain balance and reduces strain on your back.

- Lift with the Legs: Use the strength of your leg muscles to lift heavy objects, which are more powerful than back muscles.

Carrying Techniques:

- Distribute Weight Evenly: Ensure that the weight is evenly distributed on both sides of your body to prevent imbalance and reduce the risk of injury.

- Avoid Carrying Heavy Objects Over Long Distances: Use mechanical aids or ask for assistance to minimize carrying heavy loads over extended distances.

Using Carts and Dollies:

- Minimize Manual Carrying: Use carts and dollies to transport heavy items, reducing the physical strain on your body.

- Ensure Proper Use: Make sure carts and dollies are in good working condition and used correctly to prevent accidents.

Stretching and Strengthening Exercises to Prevent Injuries

Stretching Exercises:

- Regular Stretching: Incorporate regular stretching into your routine to maintain flexibility and reduce muscle tension. Stretching before and after shifts can help prevent injuries.

- Focus on Key Areas: Stretch muscles that are heavily used, such as the back, shoulders, arms, and legs.

Strengthening Exercises:

- Core Strength: Engage in exercises that strengthen the core muscles, which support the spine and help prevent back injuries.

- Overall Muscle Strength: Strengthen all major muscle groups to improve overall body stability and reduce the risk of musculoskeletal injuries.

Monitoring and Evaluation

Conducting Ergonomic Assessments and Audits

Ergonomic Checklists: Use standardized checklists to identify potential ergonomic hazards. These checklists help in recognizing ergonomic risks in the workplace and serve as a foundation for assessing compliance with ergonomic standards.

Regular Audits: Schedule periodic audits to ensure ongoing ergonomic compliance. Regular audits continuously evaluate workstations and practices for ergonomic requirements and allow for necessary improvements.

Using Feedback from Staff to Improve Ergonomic Solutions

Feedback Collection: Encourage staff to report ergonomic issues and provide suggestions. Employees can share the ergonomic problems they encounter in their daily tasks and suggest potential solutions, contributing to ergonomic improvements.

Continuous Improvement: Implement changes based on feedback to enhance workplace ergonomics. Consider employee feedback to make continuous improvements in workstations and work practices.

Tracking Injury Reports and Identifying Trends

Injury Tracking: Maintain records of workplace injuries related to ergonomics. Injury records are used to document and analyze ergonomic issues occurring in the workplace.

Trend Analysis: Analyze data to identify common issues and set improvement goals. By analyzing injury records and feedback, identify ergonomic problems, detect common trends, and set targets for improvement.